Content Source: 2021 Timbersled SX 120 / ARO / RIOT Owner’s Manual (9931501 R01) > Maintenance Chapter

| IMPORTANT |

|

The Owner's Manual for this vehicle contains warnings, instructions and other information you must read and fully understand before safely riding or performing maintenance on this vehicle.Always follow the warnings and instructions in Owner's Manual. Click the CONTENTS link above for the Table Of Contents, or download a full PDF of the Owner Manual in the Owner Support area of Polaris.com |

|

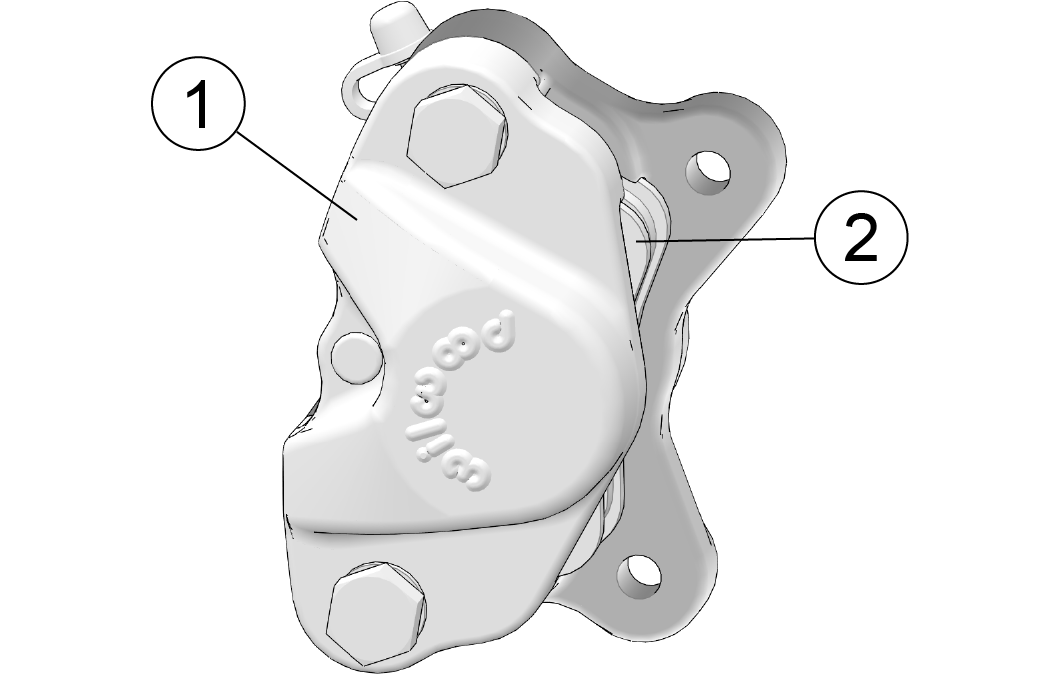

Brake failure during operation can result in serious injury or death. Properly functioning brakes are vital to your safety.

Be sure the brake pads do not drag on the disc and that brake lever travel is not excessive. Always replace brake pads when

the brake pad material becomes thinner than 1/16 inch (1.5 mm).

|

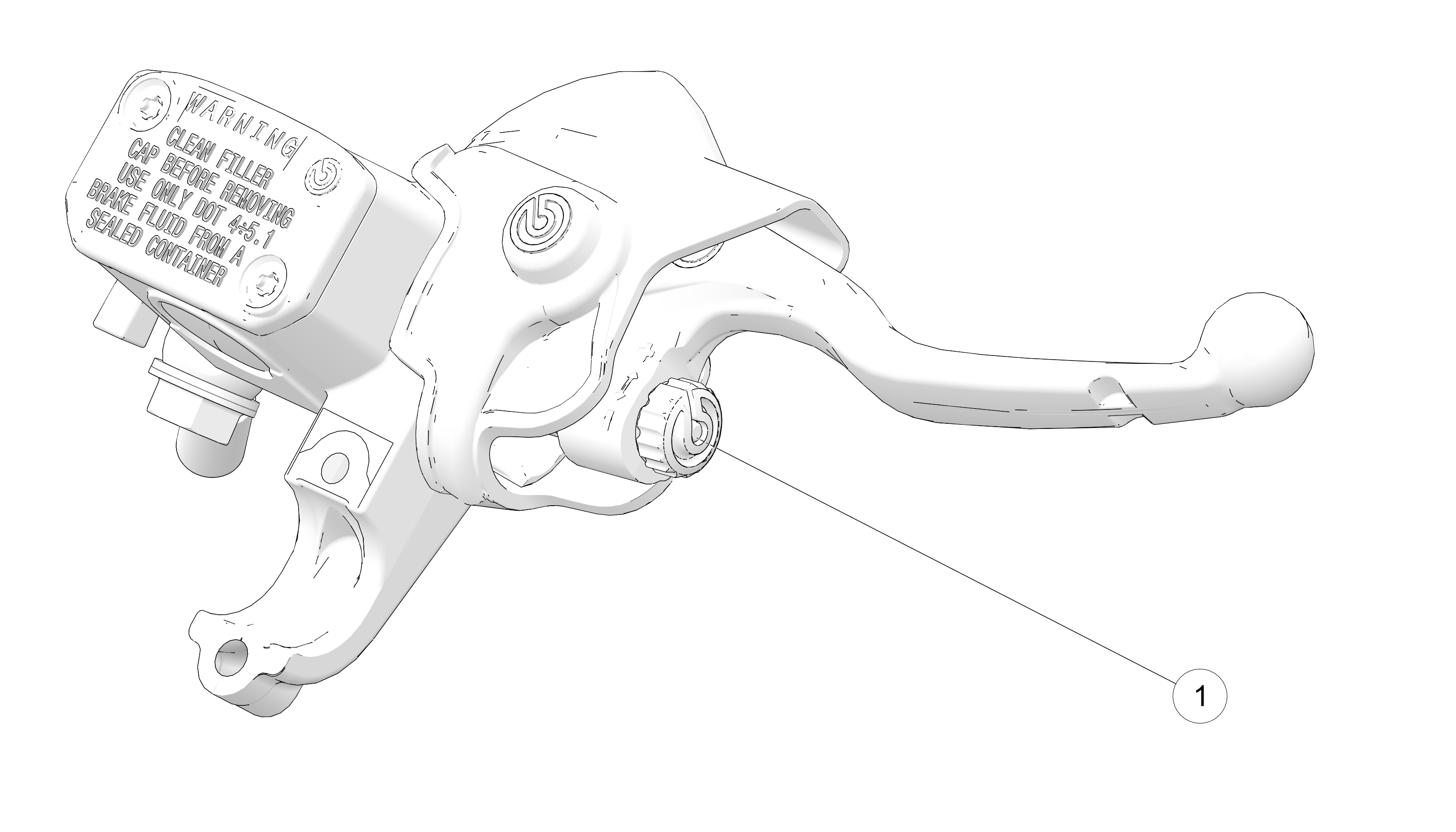

| DO NOT adjust the brake lever closer than 1/2 in from the handlebar. Adjusting the lever closer than 1/2 in could prevent the brakes from functioning properly resulting in severe injury or death. |

| NOTICE |

|

Do not attempt to force the adjustment screw beyond its limits. |

| TIP |

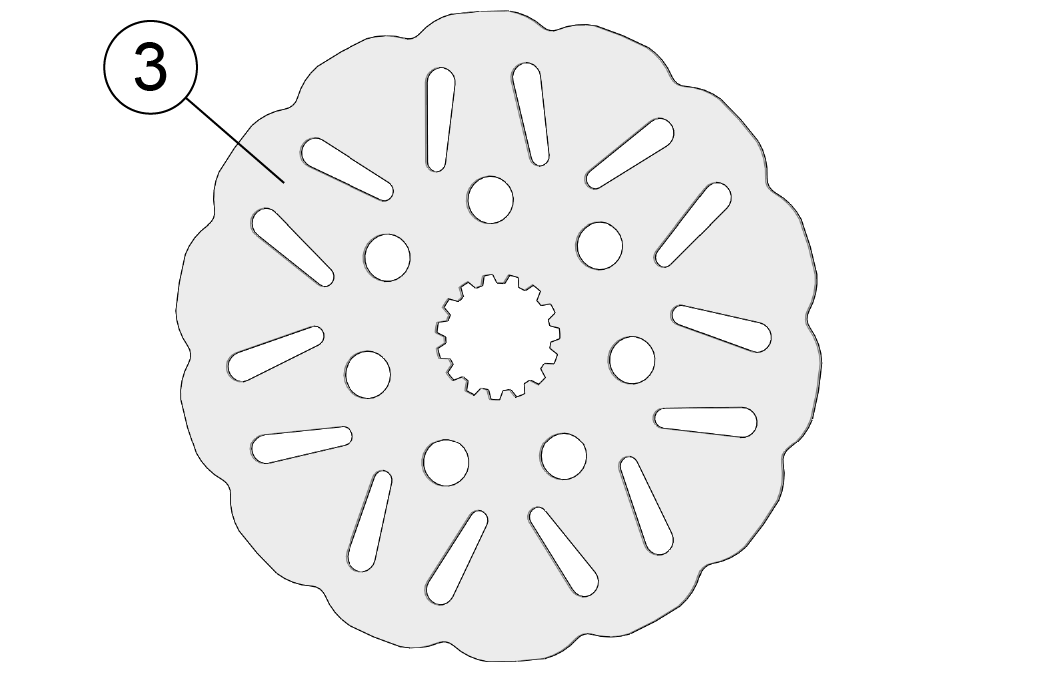

| The lightweight brake discs have vent holes that may cause a high-pitched sound during operation. |

| After opening a bottle of brake fluid, always discard any unused portion. Never store or use a partial bottle. Brake fluid is hygroscopic, meaning it rapidly absorbs moisture from the air. The moisture causes the boiling temperature of the brake fluid to drop, which can lead to early brake fade and the possibility of accident or serious injury. |

| Keep the master cylinder cover free of dirt and debris. The vent slits allow for diaphragm movement, and if they become plugged, movement of brake fluid below the diaphragm may be restricted, altering brake function. |

| NOTICE |

| Brake fluid will damage labels, paint and some plastics. Always wipe up spills immediately. |

|

Operating the vehicle with a spongy brake lever can result in loss of brakes, which could cause an accident and lead to serious

injury or death. Never operate the vehicle with a spongy-feeling brake lever.

|

|

Overfilling the master cylinder leaves no room for fluid expansion and may cause the brakes to lock, resulting in serious injury or death. Always add brake fluid to the fill line as recommended. |

| TORQUE | |

| 6–8 in lbs (0.7–0.9 Nm) |

© Copyright Polaris Inc. All rights reserved.