Content Source: 2021 Indian Vintage Dark Horse / Indian Vintage / Indian Springfield Dark Horse Owner’s Manual (9939979 R01) > Maintenance Chapter

| IMPORTANT |

|

The Owner's Manual for this vehicle contains warnings, instructions and other information you must read and fully understand before safely riding or performing maintenance on this vehicle.Always follow the warnings and instructions in Owner's Manual. Click the CONTENTS link above for the Table Of Contents, or download a full PDF of the Owner Manual in the Owner Support area of Polaris.com |

| IMPORTANT |

| Drive belt adjustments should be performed by an authorized Indian dealer, or an equivalent technician. |

| IMPORTANT |

|

Perform this procedure to achieve proper belt tension and alignment. Belt tension should be set before performing the alignment procedure.

|

|

A drive belt that is not properly tensioned can cause drive line noise and damage the drive belt, causing possible belt failure

and loss of control of the motorcycle.

|

| NOTICE |

|

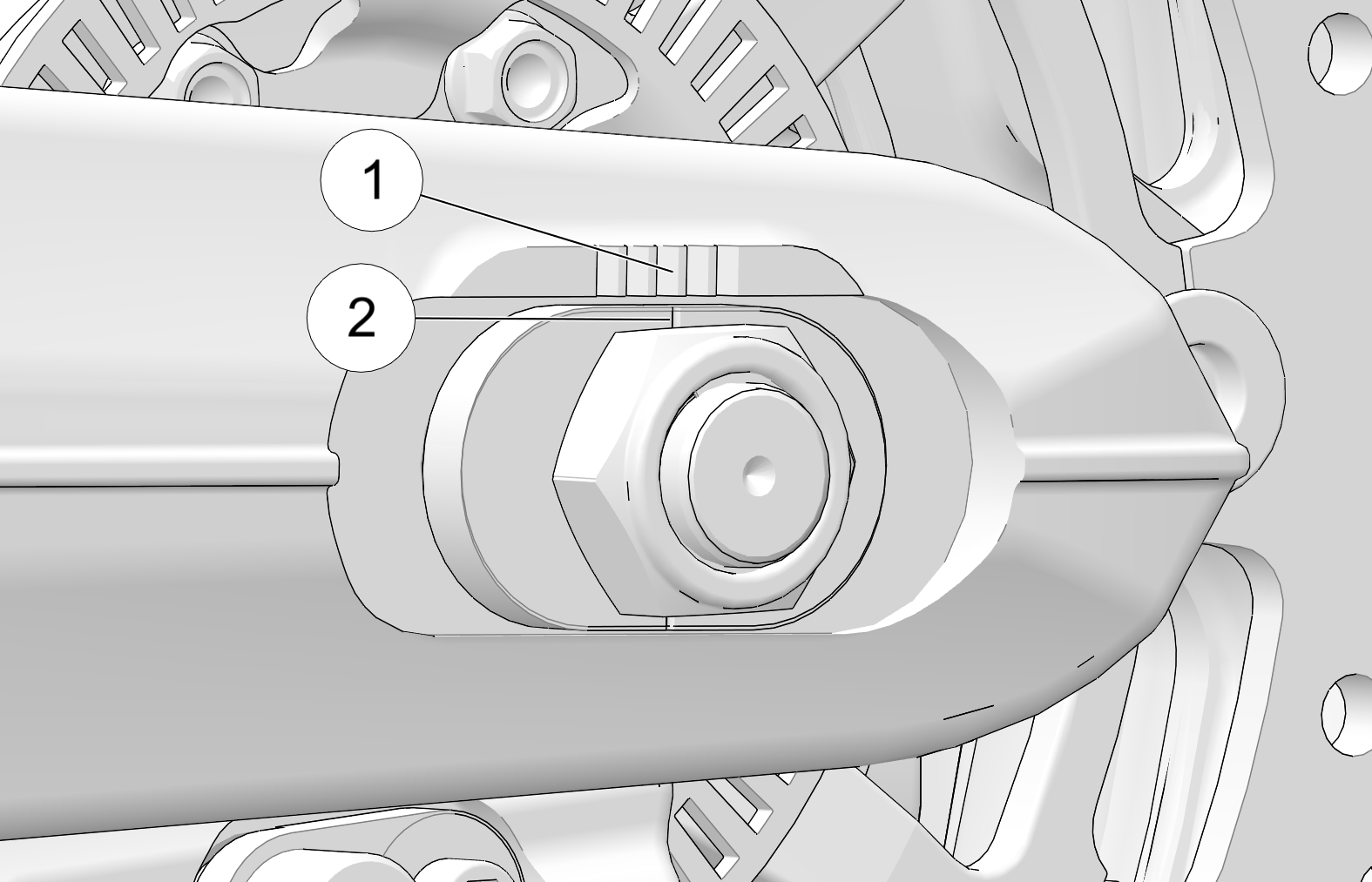

Marks |

| TORQUE | |

|

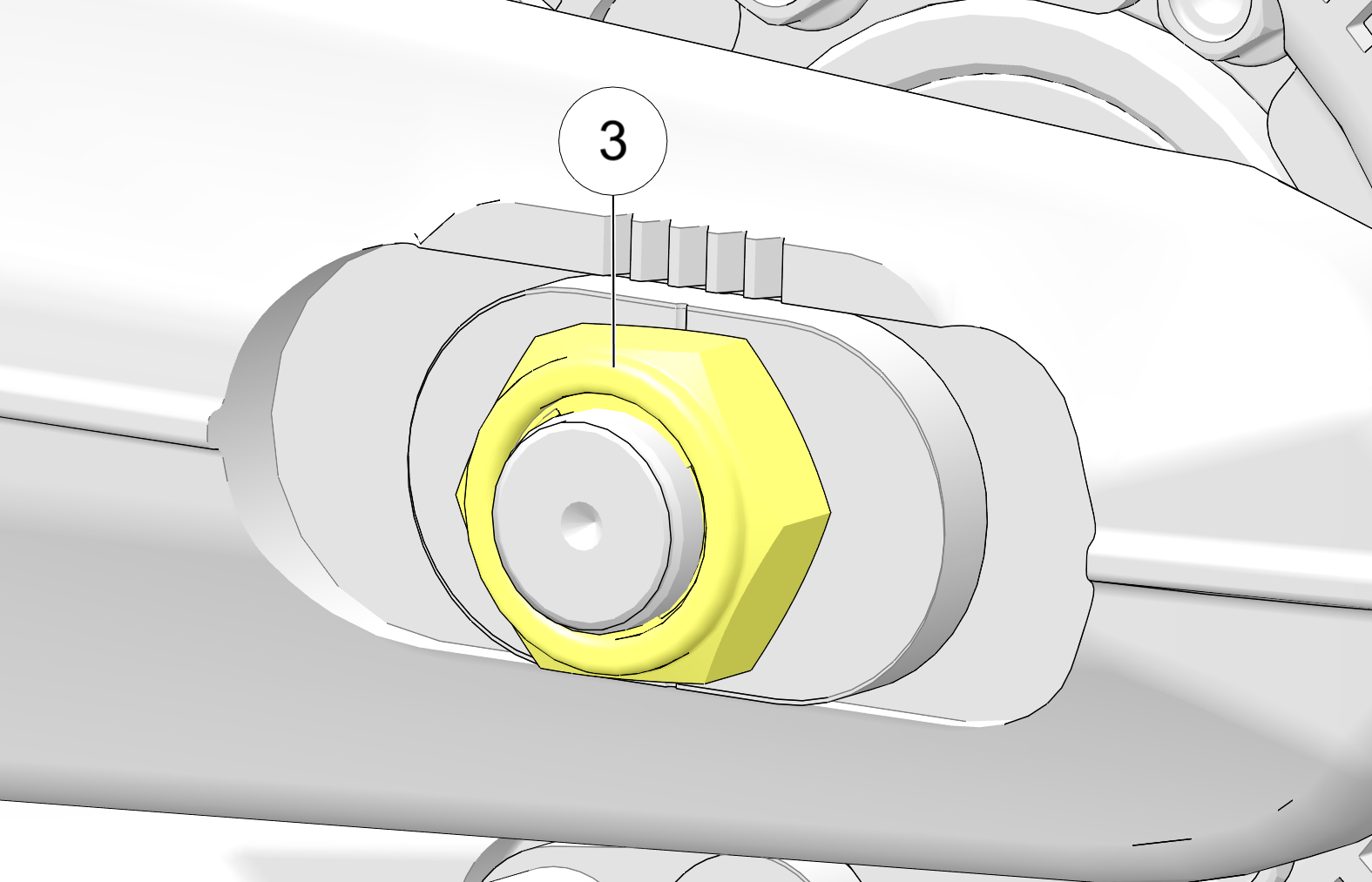

Axle Nut Torque (ADJUSTMENT SPECIFICATION): Initial Torque: 15 ft lbs (20 Nm)

|

| Belt Deflection | |

|---|---|

| Model | Deflection @ 10 lbs force |

|

Chief / Chief Dark Horse / Vintage |

1.1” (28 mm) |

|

Springfield / Chieftain / Chieftain Dark Horse / Roadmaster |

1.3“ (34 mm) |

|

A drive belt that is not properly aligned can cause drive line noise and damage the drive belt, causing possible belt failure

and loss of control of the motorcycle.

|

| NOTICE |

|

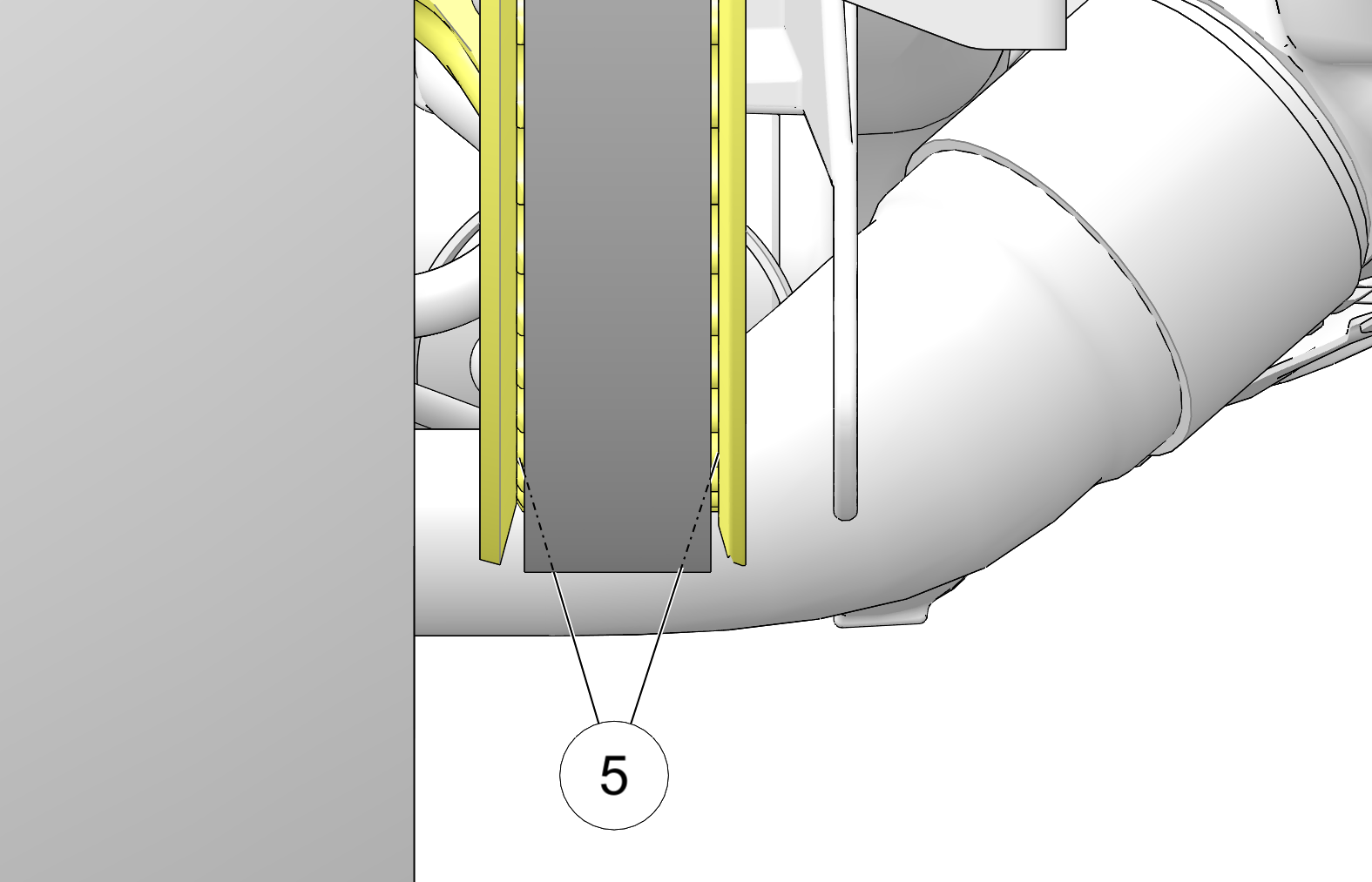

To minimize change in belt tension, use LEFT SIDE adjuster only to make final adjustments to belt alignment. |

| IMPORTANT |

| The belt should track to the center of the sprocket tooth surface when properly aligned |

| NOTICE |

|

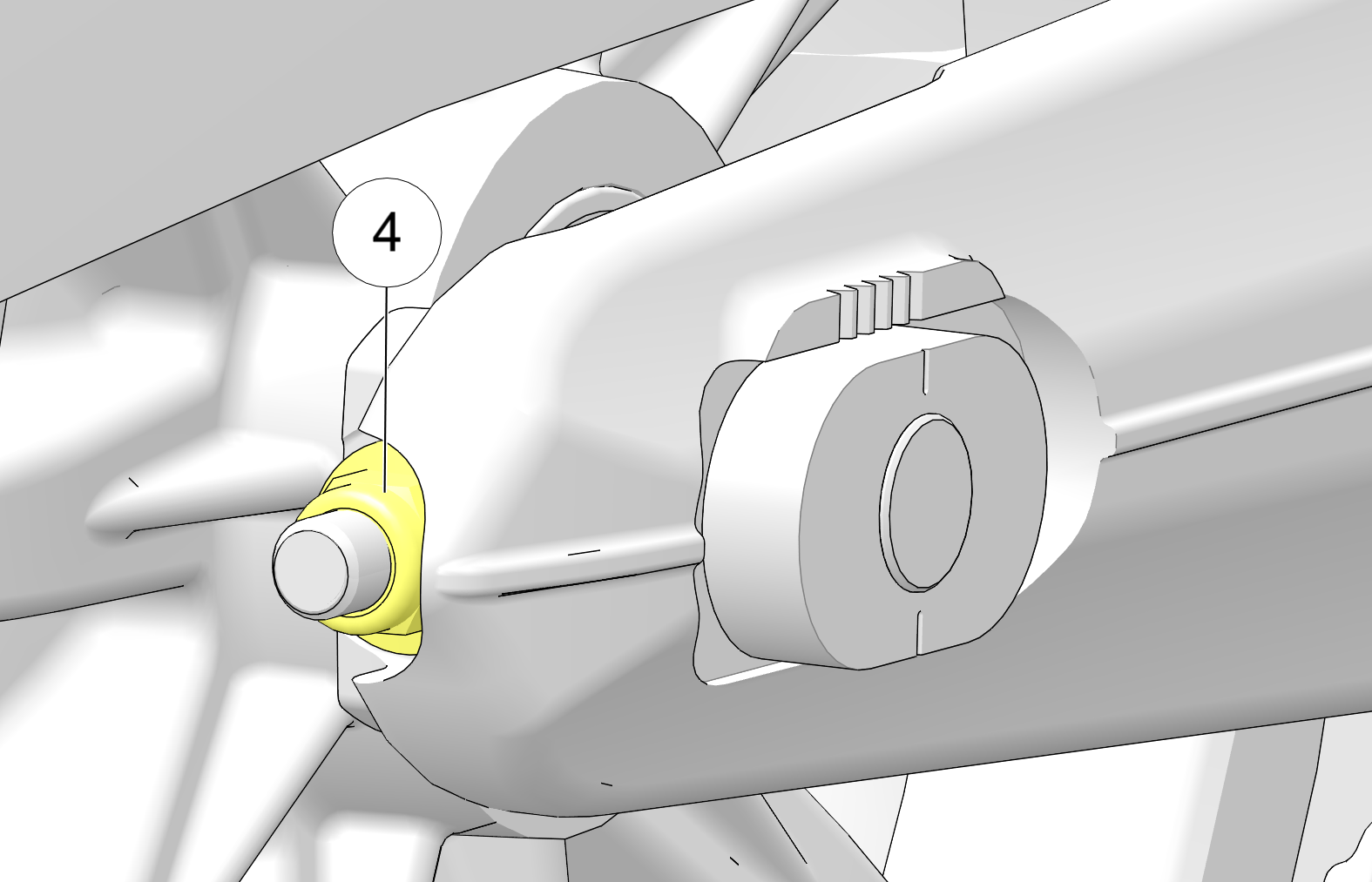

It may be necessary to loosen the axle nut and tap the left end of the axle to ensure it moves forward when the adjuster is loosened. The axle nut must be retightened to the ADJUSTMENT SPECIFICATION before proceeding. |

| TORQUE | |

|

Axle Nut Torque (FINAL TIGHTENING): Final Torque: 65 ft lbs (88 Nm) |

© Copyright Polaris Inc. All rights reserved.