Content Source: 2021 Timbersled SX 120 / ARO / RIOT Owner’s Manual (9931501 R01) > Maintenance Chapter

| IMPORTANT |

|

The Owner's Manual for this vehicle contains warnings, instructions and other information you must read and fully understand before safely riding or performing maintenance on this vehicle.Always follow the warnings and instructions in Owner's Manual. Click the CONTENTS link above for the Table Of Contents, or download a full PDF of the Owner Manual in the Owner Support area of Polaris.com |

|

Broken track rods can cause a rotating track to come

off the snow bike, which could cause serious injury or death. Never

operate

with a damaged track.

Never rotate a damaged track under power.

|

| NOTE |

|

The track is properly aligned when

he track clips |

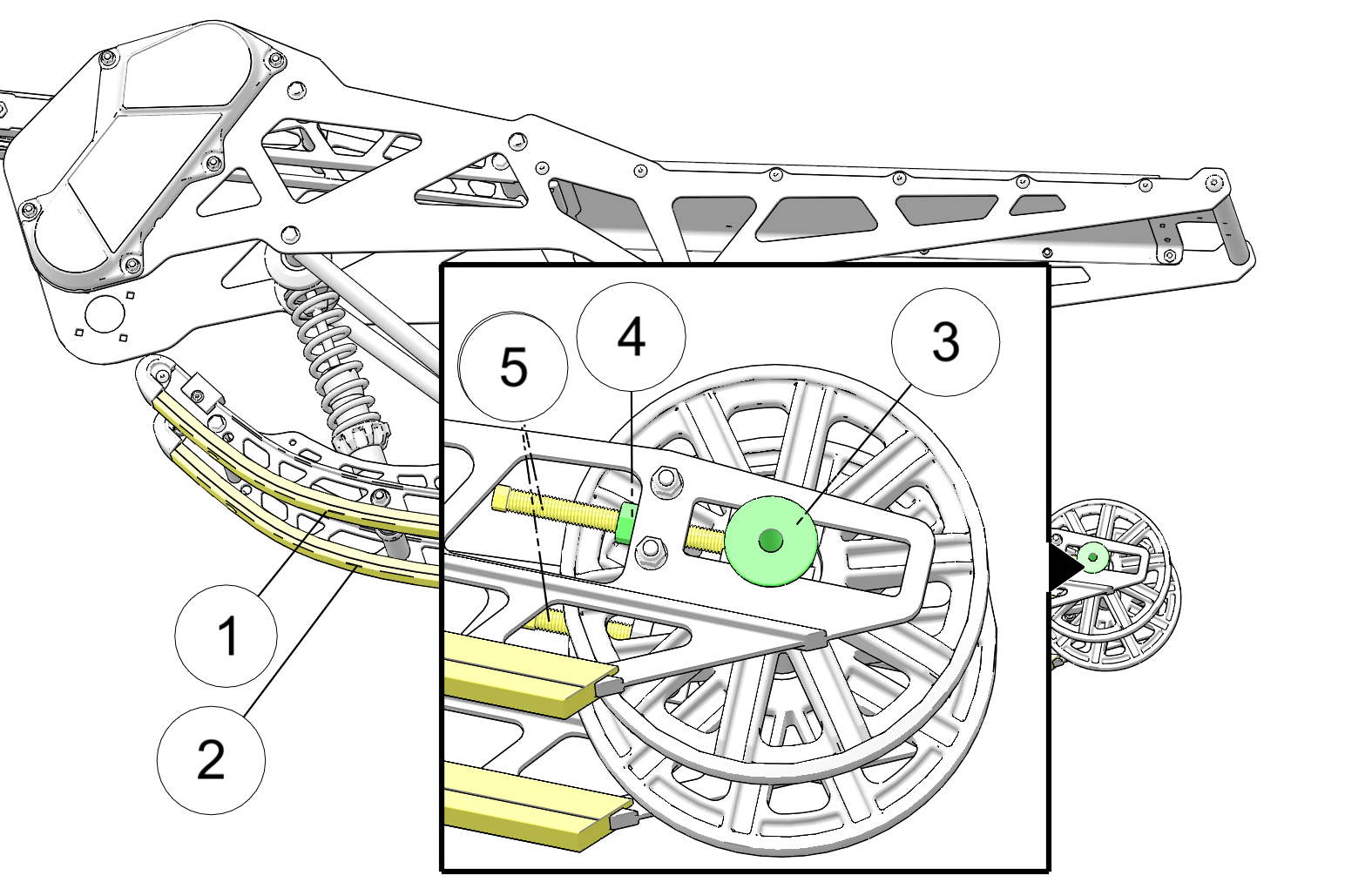

If the track is running too far to one side, track alignment must be adjusted. See Adjusting Track Alignment section for proper adjustment procedure.

If the track is running too far to the

right, turn the left tension adjustment bolt ![]() clockwise approximately one-half turn.

clockwise approximately one-half turn.

| NOTICE |

| Tune the adjustment bolt one half-turn at a time. Check the alignment between adjustment to determine if additional adjustment is needed. |

| TORQUE | |

|

Axle Bolt 36.9 ft-lbs (50 N·m) |

| IMPORTANT |

|

Adjusting track alignment will alter the tension of the

track. When track is properly aligned, measure track tension and adjust

if necessary. See

Track Tension section for more information.

|

|

Moving parts can cut and crush body parts. When performing

the checks and adjustments recommended on the following pages,

stay clear of all moving

parts. Never perform track measurement or adjustments with the engine

running.

|

| Always ensure proper track tension. Operating your snow bike with a too loose or too tight track could cause the rails to pierce the track (stabbing). Stabbing a track may result in bodily harm and / or damaged equipment. |

| NOTICE |

| Before measuring and adjusting track tension, ensure the track is properly aligned. For more information, see Track Alignment section. |

| TRACK TENSION DATA | |||

| SUSPENSION | PROPER SLACK MEASUREMENT | APPLIED WEIGHT | MEASUREMENT LOCATION - |

| All Model Types | 3/4” to 1” | 10 lbs | 10” to 15” in front of the rear axle |

If the slack measurement ![]() is less or greater than the proper slack measurement

( 3/4” to 1”), the track tension should be adjusted (see the following

section, Adjusting Track Tension).

is less or greater than the proper slack measurement

( 3/4” to 1”), the track tension should be adjusted (see the following

section, Adjusting Track Tension).

| NOTICE |

| If the track starts to skip on the drivers, the track is too loose and needs to be adjusted. Occasionally this will happen after a new track has been run. |

Turning the adjustment bolts ![]() on each side of the bike to the right will push the rear axle

on each side of the bike to the right will push the rear axle ![]() back and tighten track tension.

back and tighten track tension.

Turning

the adjustment bolts ![]() on each side of

the bike to the left will

allow the rear axle

on each side of

the bike to the left will

allow the rear axle ![]() to move forward

toward the front of the bike putting less tension on the track.

to move forward

toward the front of the bike putting less tension on the track.

| TORQUE | |

|

Axle Bolt 36.9 ft-lbs (50 N·m) |

If the slack

measurement ![]() is within the proper

slack measurement range, your track tension is set properly.

is within the proper

slack measurement range, your track tension is set properly.

If the tension is still too loose or too tight, repeat the steps above until your track tension is set properly.

© Copyright Polaris Inc. All rights reserved.