Content Source: 2020 600/800 HO/850 AXYS Conventional Tunnel Owner’s Manual (9929775 R02) > Maintenance Chapter

| IMPORTANT |

|

The Owner's Manual for this vehicle contains warnings, instructions and other information you must read and fully understand before safely riding or performing maintenance on this vehicle.Always follow the warnings and instructions in Owner's Manual. Click the CONTENTS link above for the Table Of Contents, or download a full PDF of the Owner Manual in the Owner Support area of Polaris.com |

| Moving parts can cut and crush body parts. When performing the checks and adjustments recommended on the following pages, stay clear of all moving parts. Never perform track measurement or adjustments with the engine running. |

| Broken track rods can cause a rotating track to come off the snowmobile, which could cause serious injury or death. Never operate with a damaged track. Never rotate a damaged track under power. |

| NOTE |

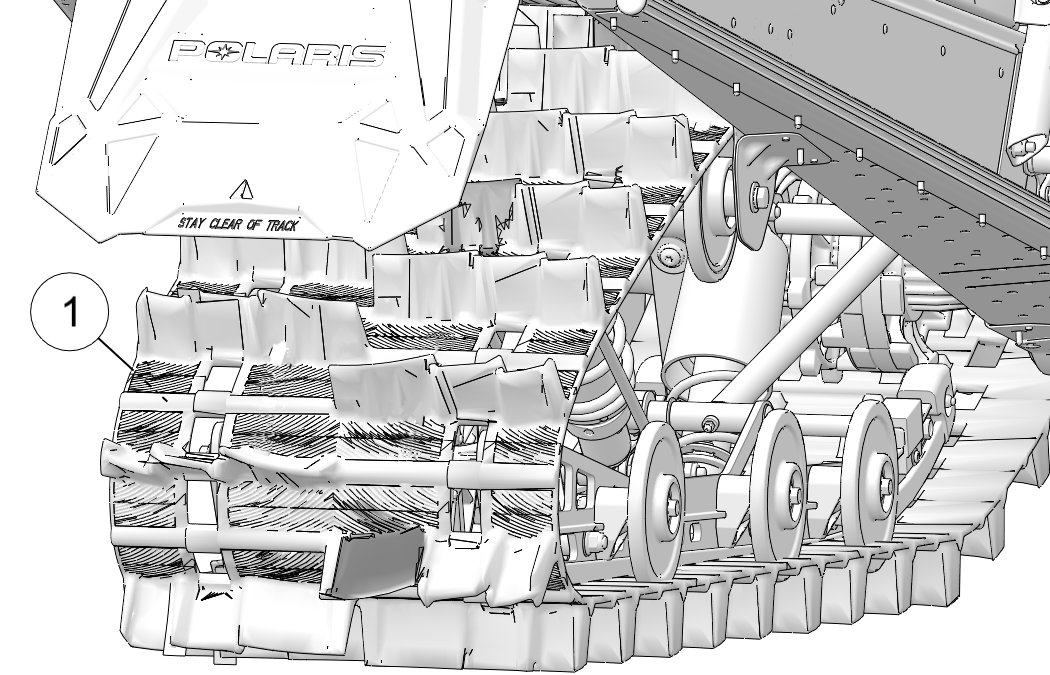

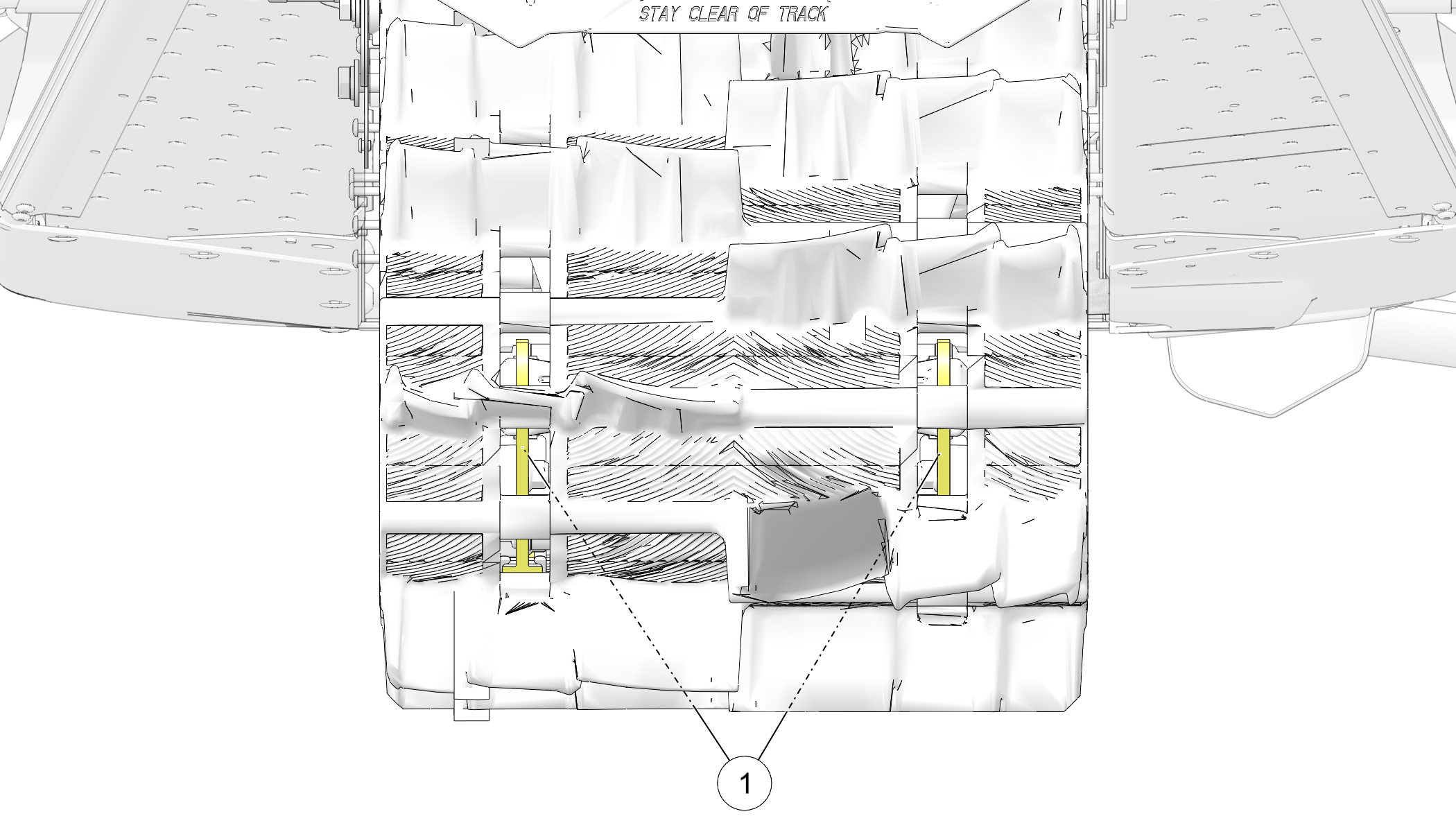

| The figures below are for reference only. Your model may differ slightly. |

| Operating with insufficient lubrication between the rail slide and track guide clips can cause track failure, loss of vehicle control and loss of braking ability, which can result in serious injury or death. Avoid operating for extended periods on ice and other surfaces that have little or no snow for lubrication. |

|

TRACK TENSION DATA CHART |

|||

|---|---|---|---|

|

Suspension |

Slack Measurement |

Weight |

Measurement Location |

|

All Models |

7/8-1 1/8 inch (2.2-2.6 cm) |

10 lbs. (4.54 kg) |

16 inches (40 cm) ahead of rear idler shaft |

| TIP |

|

Tension adjustments should be made only after the track

is warmed up and limber. |

If the track needs adjustment:

| TIP |

|

Check more frequently when the snowmobile is new. |

| TORQUE | |

|

35 ft. lbs. (47.5 Nm) |

© Copyright Polaris Industries Inc. All rights reserved.