As the riding season

draws to a close, Polaris recommends riders begin treating their snowmobile’s

fuel system with Polaris

Carbon Clean or similar commercially-available fuel

stabilizer.

Treating the fuel

system with Carbon Clean during the last few rides of the season ensures

the entire fuel system is treated.

Then, when it comes time to store the snowmobile,

all the rider has to do is completely fill the fuel tank with fresh,

non-oxygenated

fuel and treat the new fuel with Carbon Clean.

It is also recommended riders use non-oxygenated fuel

during the last rides of the season as non-oxygenated fuel stores

better

than oxygenated fuel and resists water vapor absorption.

If the rider was unable to treat the fuel system and/or

use non-oxygenated fuel at the end of the riding season, the rider

should do the following:

- The rider should

consume as much fuel in the fuel tank as possible during the last

rides of the season.

- When performing the

summerization storage procedures, fill the fuel tank completely with

non-oxygenated fuel. Note that most

oxygenated fuels contain ethanol. Since

ethanol is hydroscopic, oxygenated fuel will absorb a small amount

of water vapor

during the storage season and more so in

humid locations. Completely filling the tank with non-oxygenated

fuel minimizes

water vapor absorption during the storage

period and limits the amount of air and water vapor that can accumulate

in the tank.

- Treat the fuel in

the fuel tank with the recommend amount of Polaris Carbon Clean.

The recommended mixing ratio is outlined

on the bottle label.

- Position the snowmobile

outside in a well-ventilated area.

- Start and run the

engine for 10-15 minutes to distribute the treated fuel throughout

the fuel system.

| NOTICE |

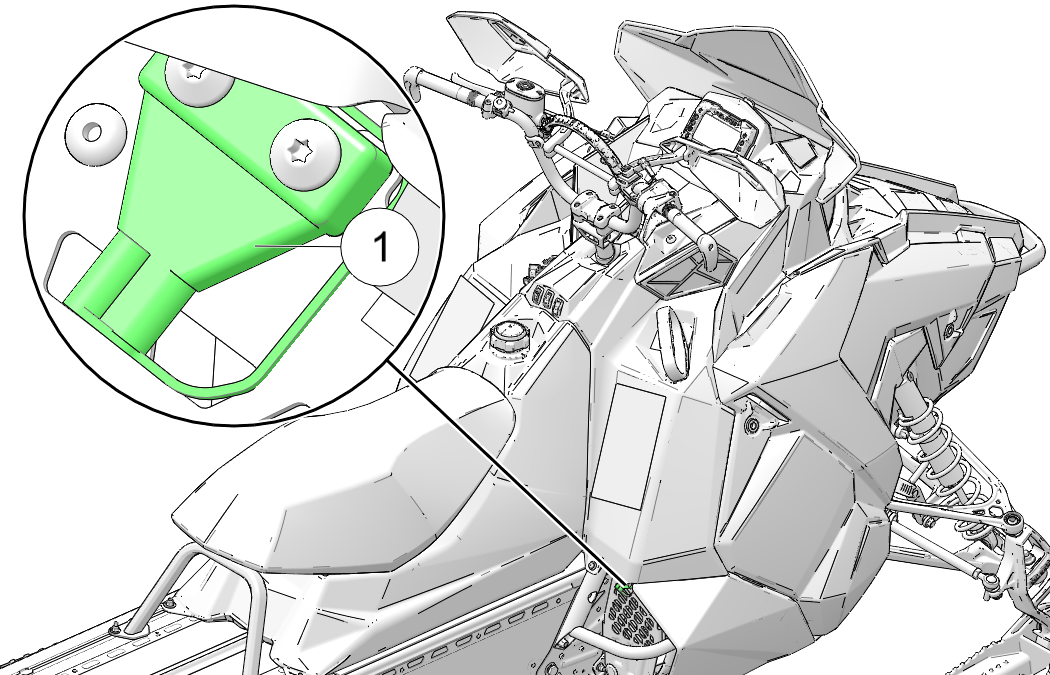

| On Carbureted engines

(550cc / 120 Youth), run the engine for 10-15 minutes and then turn

the fuel shut off valve to ‘OFF’.

Continue to run the engine

until the engine stalls and turns off. Doing this drains the carburetors

of fuel. |

![]() .

.