| IMPORTANT |

|

Moving a handlebar component without first loosening

its screws/set screws may cut grooves into the handlebar, making it

difficult

to secure the component.

Do not move a handlebar component without first loosening its mounting

screws/set screws. Take care

to avoid damaging hand

warmer/brake switch wires when moving components.

|

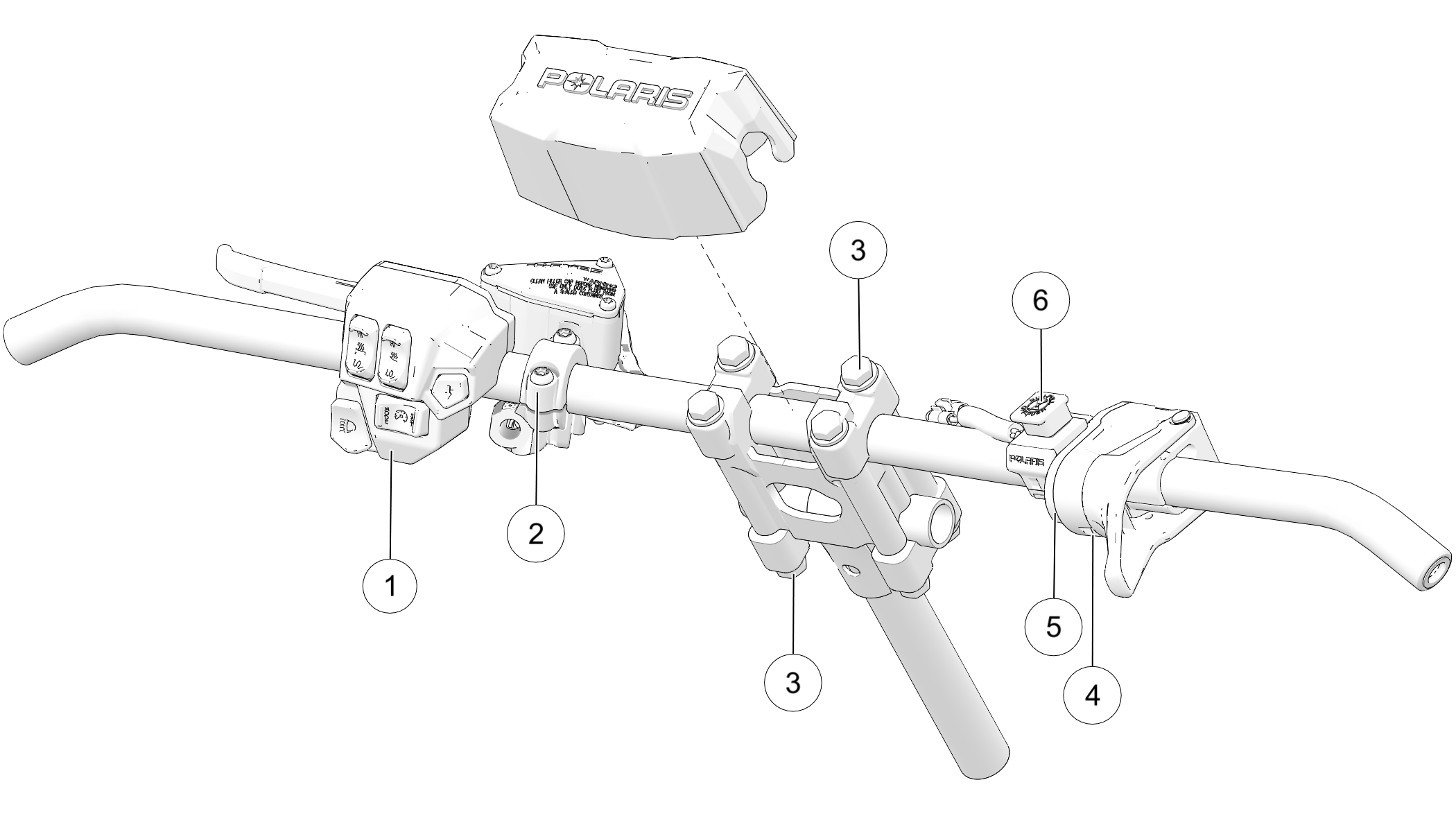

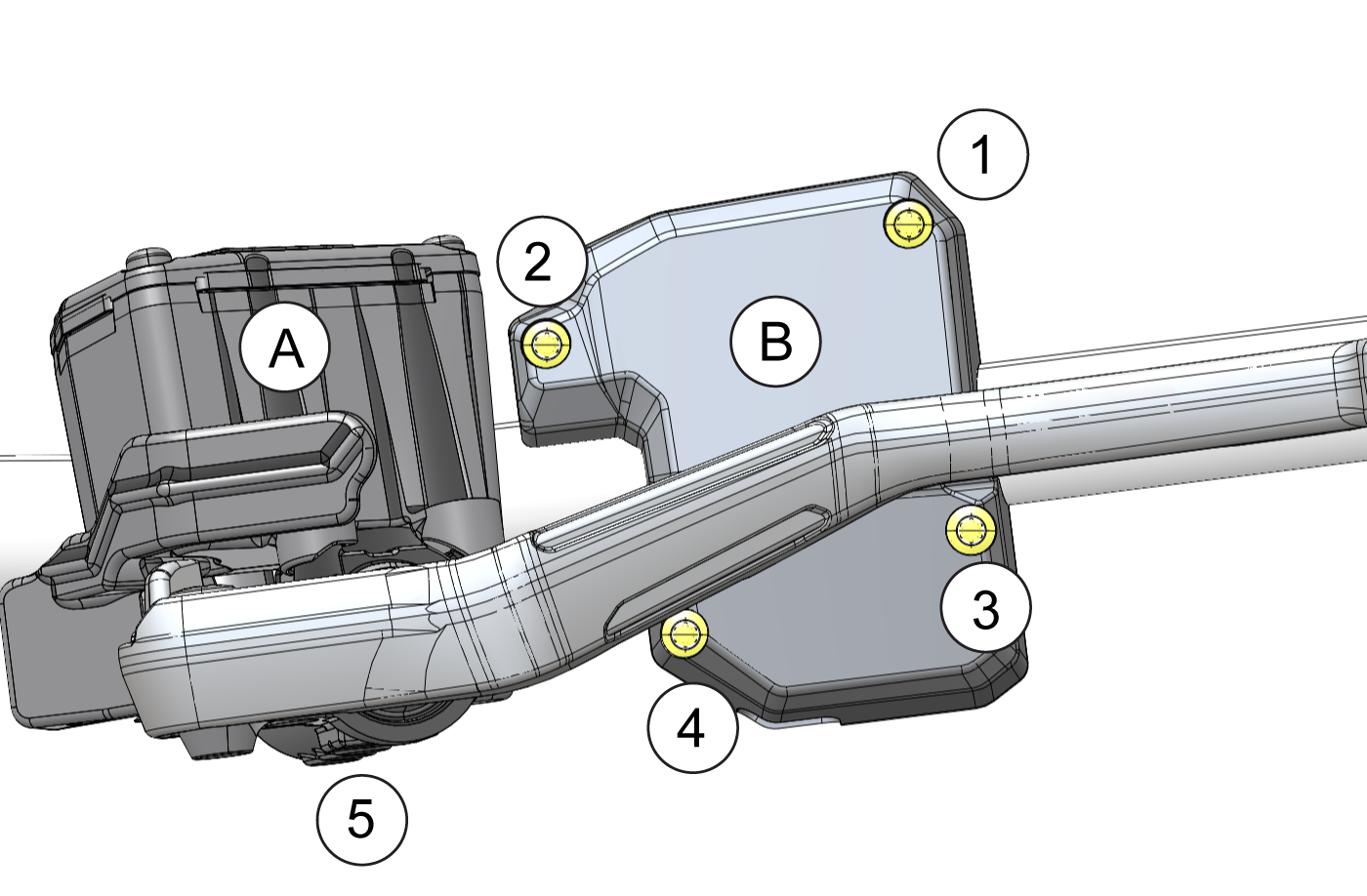

| Component | Torque DO NOT OVER-TIGHTEN |

|

|---|---|---|

| Left Handlebar Control Block | 20 in-lbs (2.3 Nm) | |

| Brake Lever / Master Cylinder Torque the front screw first, then torque the screw next to the reservoir. |

70 in-lbs (7.9 Nm) | |

| Upper / Lower Riser Clamps | 14.8 ft-lbs (20 Nm) | |

| Throttle Lever Block Set Screw | 27 in-lbs (3.1 Nm) | |

| Throttle Lever Block Cover Screws | 6 in-lbs (0.7 Nm) | |

| Auxiliary Engine Stop Switch Set Screw | 12 in-lbs (1.4 Nm) | |

| Riser | Install with the “FWD” stamp facing toward the hood | |

| Not Shown | Hand Guard Mounts (if applicable) | Hand-Tight |

| Not Shown | Mountain Hoop Bar (if applicable) | 10 ft-lbs (13.6 Nm) |

| NOTICE |

|

Do not stretch wires while adjusting the controls. Stretching the wires could damage the handwarmers. |

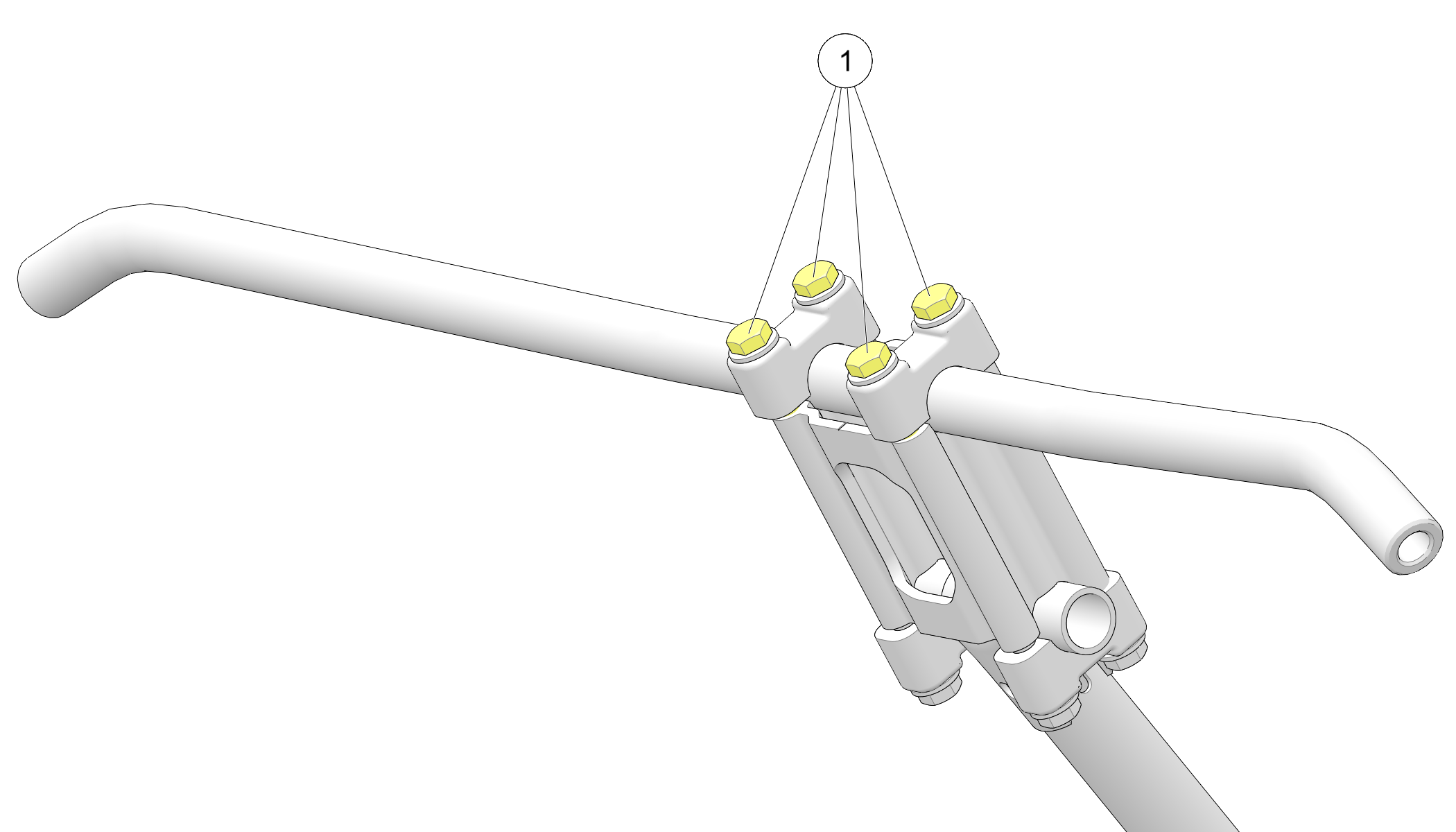

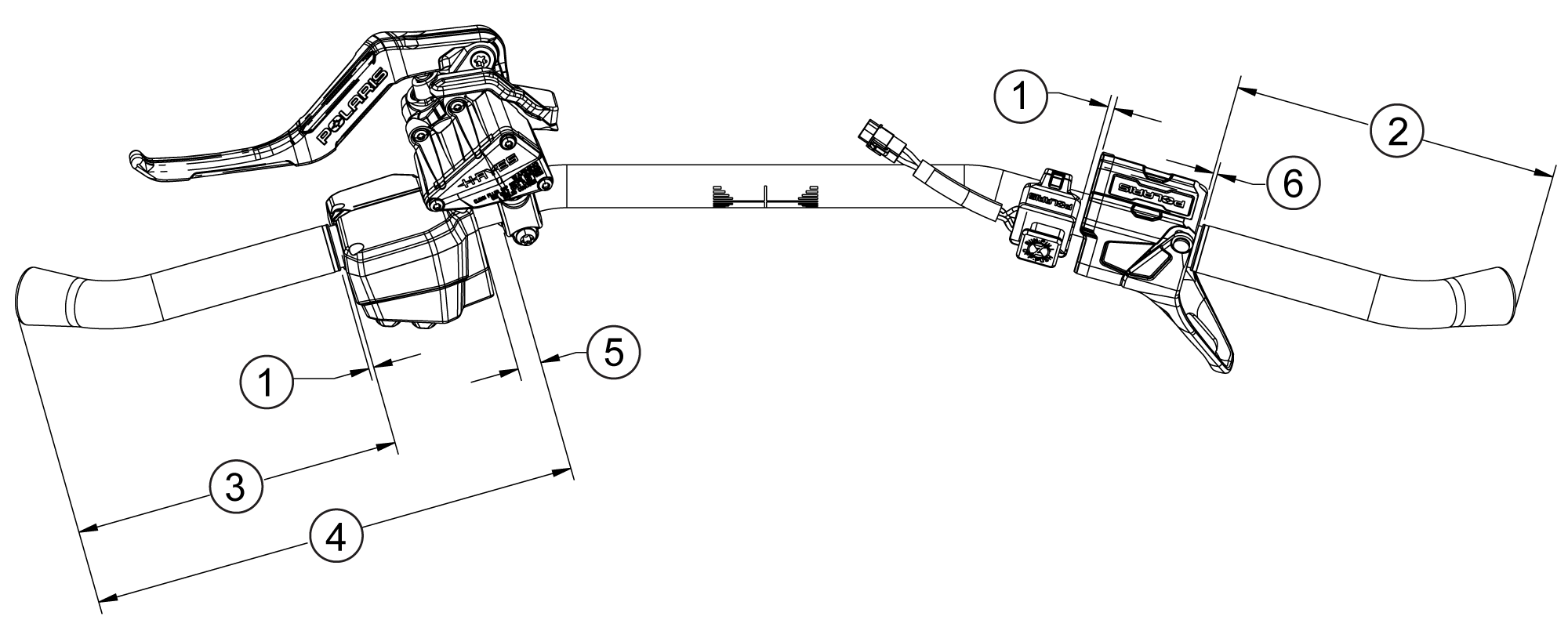

| TORQUE | |

|

14.8 ft-lbs (20 Nm) |

Riser angle can be adjusted to suit rider preference.

To adjust the riser (if equipped), do the following:

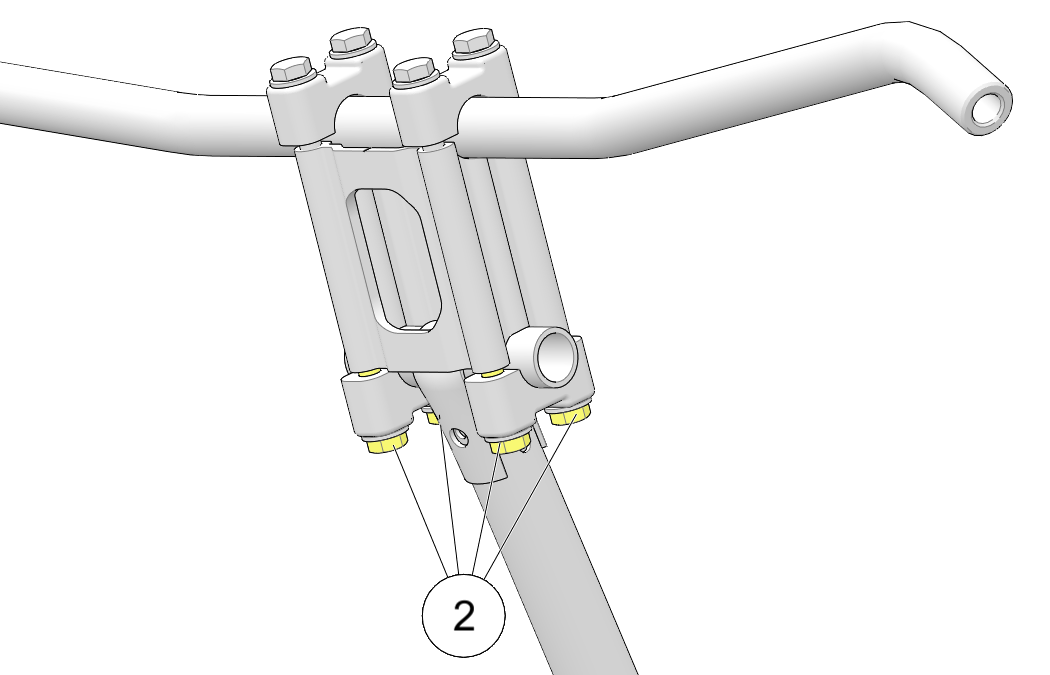

| TORQUE | |

|

Handlebar Clamp Fastener Torque:

16 ft-lbs (21 Nm)

ROX Slide Fastener Torque:

16 ft-lbs (21 Nm)

Adjuster Cranks:

Hand Tight |

| Take care to avoid damaging hand warmer/brake switch wires when moving components. |

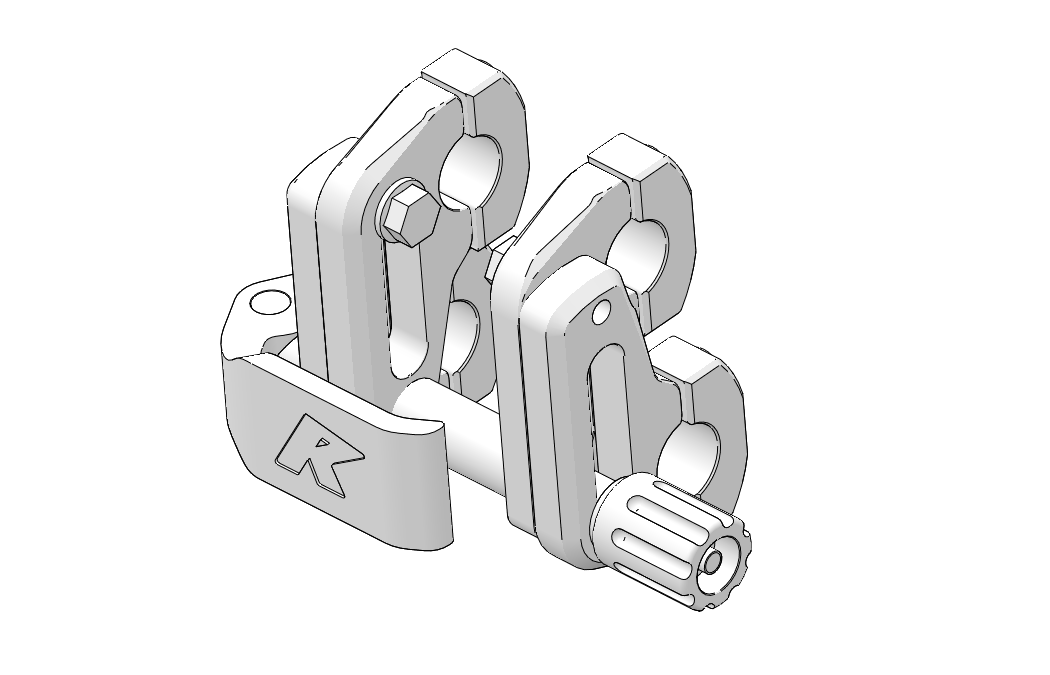

| NOTE |

| If the control is loose and was inadvertently moved without loosening the screws, move the control block slightly to the left or right to relocate the pins. |

| TORQUE | |

| 24 in-lbs (2.7 Nm) |

| TORQUE | |

| 70 in-lbs (7.9 Nm) |

© Copyright Polaris Inc. All rights reserved.