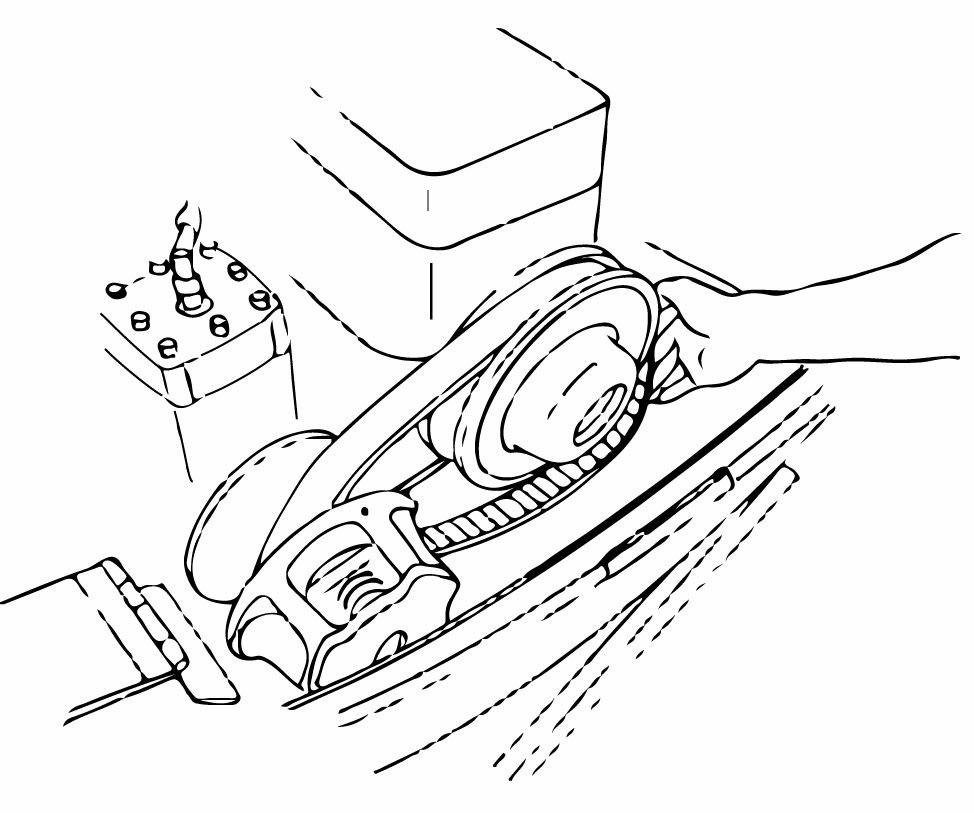

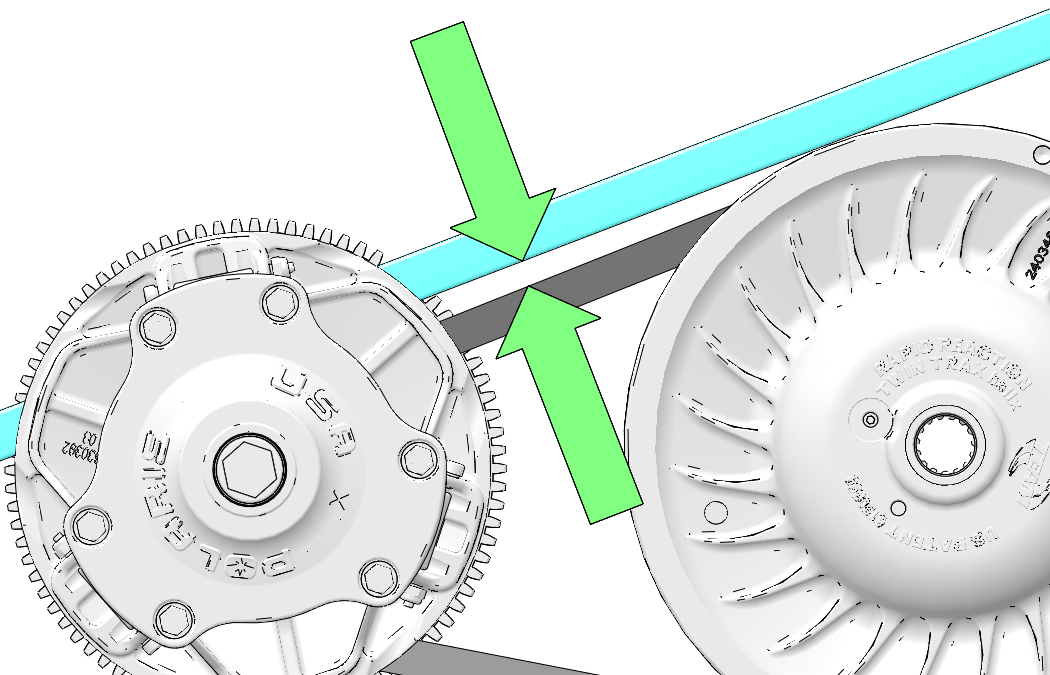

Belt width and

length must match the center distance of the clutches and sheave width

of the drive clutch. For this reason,

POLARIS recommends that only O.E.M. belts be used.

Other belts may match the dimensions, but can drastically change the

shift

pattern, resulting in poor performance.

Periodically check

the condition and tension of the drive belt, and always carry a spare.

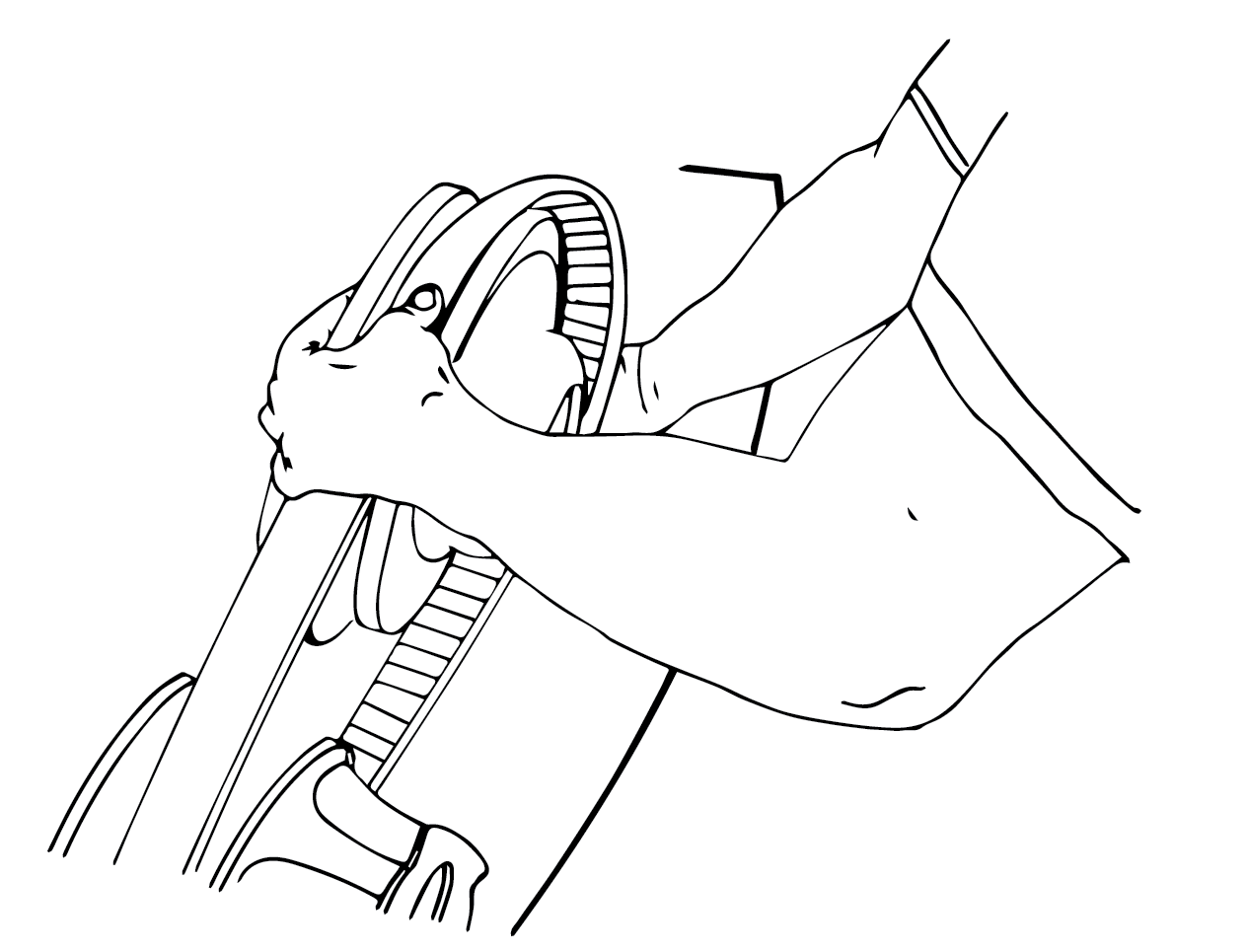

Inspect the belt for signs of excessive

wear: frayed edges, missing cogs, cracks and excessive

looseness. Replace the belt if any of these conditions exist.

| TIP |

| A worn belt will continue to function, but will not deliver maximum

performance. Always carry a spare belt in case of an emergency. |

For improved drive-away

during extremely cold temperatures, remove the belt and warm it to

room temperature. Reinstall it

before starting the snowmobile.